New Twitch Drop – Claim the Tattered Veil Cape!

Earn the new Twitch drop cape reward by watching Mortal Online 2 creators on Twitch! From 7:00 PM CEST 18th April to 7:00 PM CEST 25th April!

Earn the new Twitch drop cape reward by watching Mortal Online 2 creators on Twitch! From 7:00 PM CEST 18th April to 7:00 PM CEST 25th April!

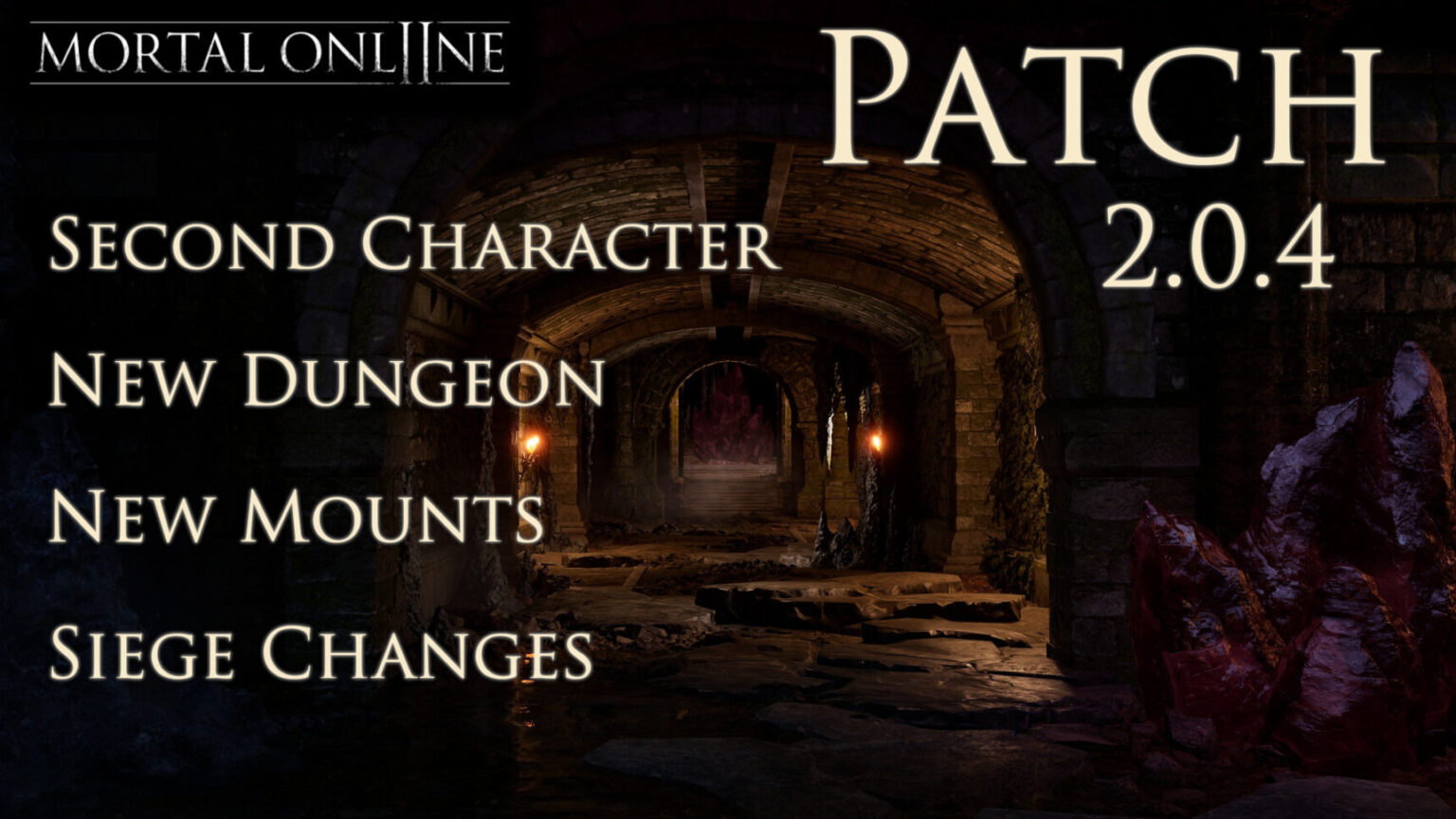

Read the patch notes for update 2.0.4 here! Introducing a second character slot, new dungeon, new mounts, siege changes and more!

Follow the link to our feedback questionnaire and let us know your thoughts about the Sprint 2 Patch PTR.

Mortal Online 2 is a fantasy MMORPG like no other.

A persistent sandbox world filled with thousands of players, together they fill the realm of Nave with content and unique stories.

Mortal Online 2 is first and foremost a player – driven game. It is the players who gather resources, craft goods, set up trade routes, build houses, fortifications, and villages – wage wars, or keep the peace.

What you choose to do in Nave is entirely up to you.

Stay in the relative safety of protected cities, or risk venturing out into uncharted regions for resources and treasure, or seek out monsters of legend to test your mettle.

Fight and kill other players – or protect the people around you from marauders and mischief, for bounties or renown.

Profit from gathering, taming, refining, crafting, construction, trade, protection, and more.

Join a guild to compete for trade or territory, build keeps and engage in epic wars.

All these paths are open to you, and you can travel them alone or together with others. No matter what you choose, your time in Nave is guaranteed to be an unparalleled experience, exclusive to you, and forever written into its persistent history.

This isn’t our game, it is yours.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Tune in to Henrik’s stream on Thursday, August 19th at 18:00 UTC for updates regarding our upcoming final stress test and launch into early access!